Product | Article | Description | Dia Range | |

| D840 | Multilayer ultra mICRO Drill | 0.050 – 0.090 mm | |

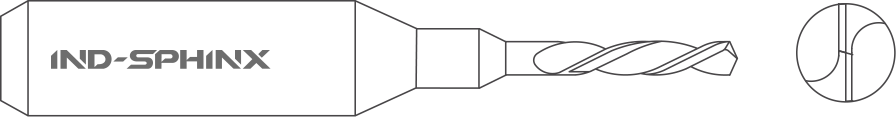

| D840 | Multilayer Super mICRO Drill | 0.100 – 0.190 mm | |

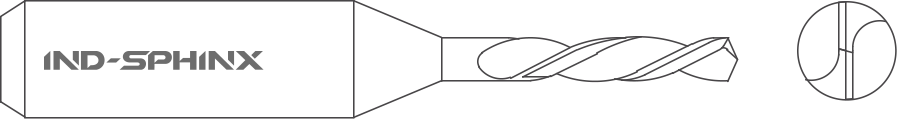

| D840 | Multilayer Drill | 0.20 – 1.15 mm | |

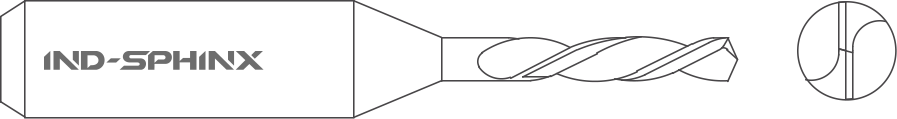

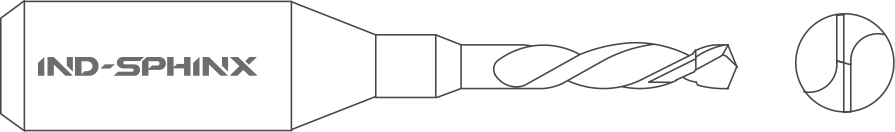

| D835 | mICRO Drill | 0.20 – 0.65 mm | |

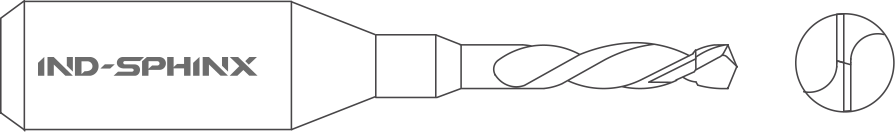

| D835 | Standard Drill | 0.70 – 3.175 mm | |

| D620 | Multilayer Undercut Drill | 0.15 – 0.65 mm | |

| D635 | Undercut Drill | 0.20 – 3.00 mm | |

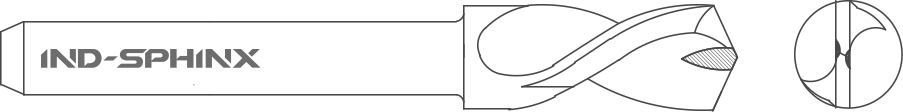

| D546 | Slot Drill | 0.30 – 3.175 mm | |

| D835 / D534 / D532 | Inverse Drill | 3.20 – 7.50 mm | |

On request:Inch sizes / Special dimensions

Troubleshooting

Hole Registration Accuracy

Hole registration accuracy is measured by an AOI machine. As shown below, hole positional accuracy is affected by some causes, therefore by countermeasure these defects we can get better accuracy results.

Roughness of Hole Wall

The below pictures shows some very rough holes caused by drilling. This defect should be controlled to get the desired quality requirements.

Swarf Clogging

Poor swarf evacuation results in swarf deposit in the drilled hole and any space between the PWB and entry board.

Resin Smearing / Wicking

Resin is melted by heat of drilling and attaches to inner and copper layer. It prevents connection with the copper.

Drill Bit Breakage

Drill breakage is of two types:

- Deflected breakage.

Radial force tends to break the drill at the end of flute. - Twisted breakage

Large torque tends to break the drill at the middle of flute